In today’s world of Industry 4.0, optimization and efficiency are key to staying competitive. Two tools that are revolutionizing the way companies operate are simulation and digital twins. But what exactly are they, and how do they differ? Let’s explore these innovative technologies and their impact on modern industry.

Simulation: What is it?

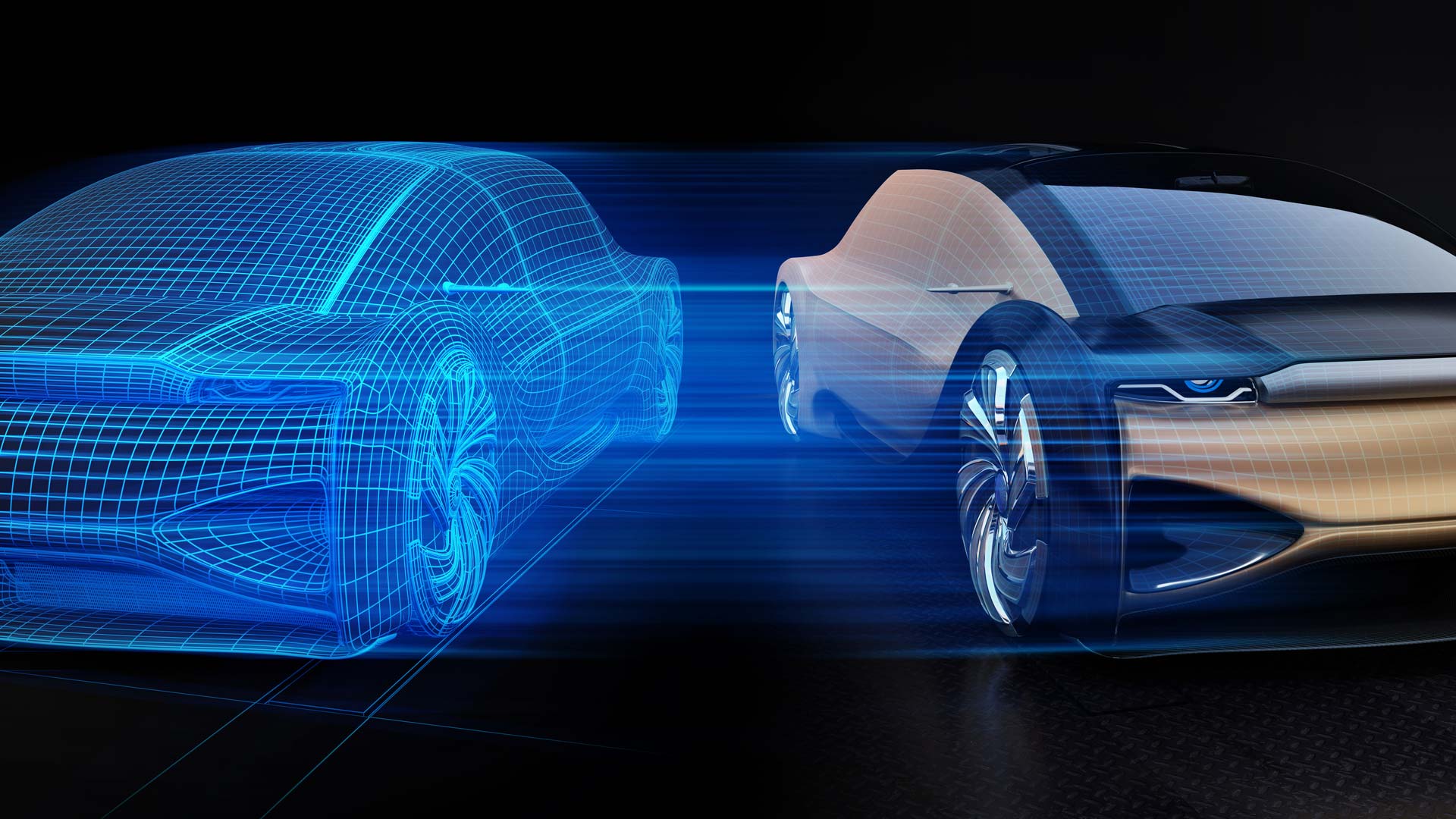

Simulation is a technique that creates a virtual representation of a real-world system or process. It allows users to model, analyze, and optimize various aspects of operations without interrupting actual processes. Imagine a car manufacturing company needing to optimize its assembly line. Instead of experimenting directly on the production line, which could be costly and disruptive, they use simulation software like AnyLogic to create a complete virtual model of their assembly line.

This model includes representations of robots, workers, and parts, allowing engineers to identify bottlenecks, test different configurations, and optimize workflow without halting real production. As a result, the company can increase production efficiency and reduce downtime, all before making a single change in the real world.

Simulation software solutions employ advanced modeling techniques such as discrete event simulation, agent-based modeling, and system dynamics. They can represent complex systems, including machinery, workers, materials, and logistics, providing a comprehensive view of the production ecosystem.

Digital Twin: What is it?

A digital twin, on the other hand, goes a step further. It is a virtual replica of a physical object, process, or system that is updated in real-time with data from the real world. While a simulation can run on historical or hypothetical data, a digital twin maintains a constant connection to its physical counterpart, allowing for continuous monitoring and analysis.

Consider a steel processing plant that implements a digital twin of its blast furnace. Sensors in the real furnace constantly send data on temperature, pressure, and chemical composition to the digital twin. This allows operators not only to monitor performance in real-time but also to predict potential issues and continuously optimize the smelting process. In one real case, a steel mill that implemented this system reduced unplanned downtime and extended the equipment’s lifespan.

Digital twins use real-time data from sensors, IoT, and other systems to reflect the current state of their physical counterpart. This enables more accurate predictions and more informed decision-making, taking process optimization to a new level.

Is Simulation the Same as Digital Twins?

Although simulation and digital twins share some similarities, they are not the same. The difference becomes clear when we consider how a logistics company might use both technologies. To plan a new distribution network, the company could use simulation, testing different warehouse locations and transportation routes in a virtual environment. This would allow them to evaluate multiple scenarios before making any physical investment.

On the other hand, for its existing warehouses, the same company could implement digital twins. These would monitor inventory, goods movement, and equipment performance in real-time. With constantly updated information, managers can make informed decisions on the spot, such as rerouting shipments or adjusting staffing levels based on current demand.

Key Differences Between Simulation and Digital Twins

- Temporality: Simulations generally model future or hypothetical scenarios, while digital twins reflect the current and real-time state of a system.

- Data Connection: Digital twins are constantly updated with real-time data, whereas simulations can use historical or hypothetical data.

- Specificity: Digital twins are tied to a specific object or system, whereas simulations can be more generic.

- Lifecycle: Digital twins typically accompany their physical counterpart throughout its lifecycle, while simulations are often used for specific projects or analyses.

- Interactivity: Digital twins allow for more direct and real-time interaction with the physical system.

When Should Each Be Used?

The choice between simulation and digital twins depends on the specific needs of the project. Simulation is ideal when you need to explore multiple hypothetical scenarios or are in the planning stages of a new system or process. For example, an electronics factory planning to introduce a new production line could use simulation to test different equipment configurations and workflows. This would allow them to determine the most efficient design before making any physical changes, potentially saving significant time and resources.

Digital twins, on the other hand, excel when there is a need to monitor and optimize an existing system in real-time or when implementing predictive maintenance. For example, a large-scale manufacturing company could implement digital twins for its global supply chain network. Each factory, warehouse, and distribution center would have a digital twin receiving real-time data on inventory levels, production rates, transportation times, and demand forecasts. This would allow the company to identify potential bottlenecks, optimize inventory levels, and dynamically adjust production schedules based on current conditions. In the event of disruptions like natural disasters or geopolitical issues, the digital twin could simulate various scenarios to quickly determine the most effective mitigation strategies. As a result, the company could significantly reduce stockouts, minimize excess inventory, and improve the overall resilience and efficiency of the supply chain.

Real-World Applications and Examples of Simulation

In practice, both simulation and digital twins are transforming various industries. In the supply chain sector, AnyLogic has been used to simulate complex logistics networks in the steel industry. A steel company used this technology to optimize the distribution of its products, reducing transportation costs by 15% and improving delivery times by 20%.

Factory layout design has also greatly benefited from simulation. A steel rolling mill used this technique to redesign its layout, resulting in a 10% increase in production and a 25% reduction in material handling time. These results demonstrate the power of simulation to improve operational efficiency without the risks associated with real-world experimentation.

Real-World Applications and Examples of Digital Twins

On the other hand, digital twins are revolutionizing how companies approach maintenance and process optimization. In a steel rolling mill, a digital twin was used to continuously adjust process parameters based on current conditions. This approach led to a 5% improvement in product quality and a 10% reduction in material waste, demonstrating the potential of digital twins for real-time continuous improvement.

In the field of supply chain management, a logistics company implemented a digital twin of its entire network, providing real-time visibility of inventory, production, and logistics. The result was impressive: a 20% reduction in inventory levels and a 15% improvement in delivery accuracy. This case illustrates how digital twins can provide a holistic, real-time view of complex operations, enabling more agile and precise decision-making.

Conclusion

In conclusion, both simulation and digital twins are powerful tools in modern industry, each with its strengths and specific applications. While simulation offers the flexibility to explore multiple hypothetical scenarios, digital twins provide a real-time connection to physical systems, enabling continuous optimization.

The choice between one or the other will depend on the specific needs of each project or system. However, in many cases, the combined use of both technologies can provide the best results, leveraging the flexibility of simulation for long-term planning and the real-time precision of digital twins for daily optimization. As these technologies continue to evolve, they promise to drive even greater efficiency and innovation across various industrial sectors.