Automation and Process Control: What is it?

Advantages and Disadvantages Automation and process control are key to making companies more efficient, reducing expenses, and making better decisions. Essentially, automation involves using technology to handle repetitive tasks. On the other hand, process control monitors and adjusts these tasks to achieve better results. Let’s delve into what automation and process control exactly entail. We’ll discuss their advantages and disadvantages, provide tips for implementation across different sectors, and take a look at future prospects in this field.

What is automation and process control?

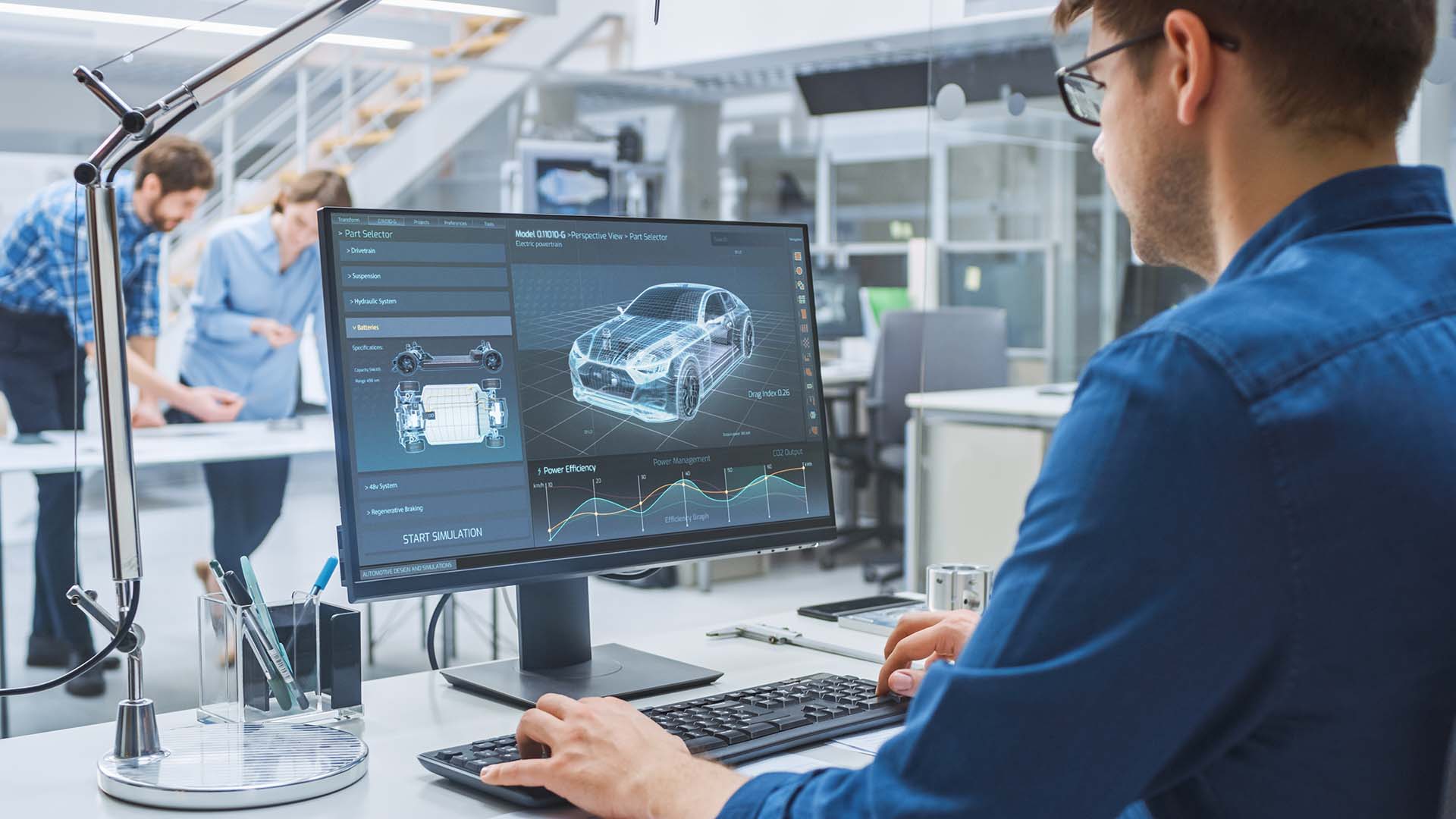

Automation utilizes technology to perform tasks autonomously, without human intervention. This includes computer systems and robots, helping companies to perform tasks such as price comparison faster and more accurately. Process control involves adjusting what automation does to improve efficiency. Both automation and control enhance how companies operate, reducing costs and enabling better decision-making. The automation and control market is rapidly expanding, with industries like agriculture and pharmaceuticals already leveraging this technology. According to Precision Reports, even the oil industry is automating its processes. Meanwhile, Industry 4.0 is revolutionizing manufacturing processes. Major brands like Siemens and ABB are leading this charge, assisting other companies in their automation efforts. In industrial automation, there are three distinct levels: supervisory level, control level, and field level. At the lowest level, terminal equipment like sensors plays a crucial role.

Advantages of automation and process control

Automation and process control offer several benefits, including:

- Increased efficiency: Automated systems execute repetitive tasks faster and more accurately.

- Cost reduction: Automating tasks decreases labor and service expenses.

- Compliance monitoring: Artificial intelligence aids in contract compliance and identifies areas for improvement.

- Informed decision-making: AI provides essential data for purchasing goods and services.

- Improved data flow and decision-making:Automation enhances communication between systems and enables rapid response to changes.

Automation is extensively used in manufacturing, logistics, robotics, automotive, and technology sectors. Algorithms predict operations without direct instructions, ensuring uninterrupted operations. Notably, automation reduces data analysis costs and minimizes the risk of machine or service failures. Using automation allows employees to focus on more valuable tasks, thereby enhancing working conditions to some extent. However, business automation poses challenges such as cultural differences and disparate approaches. It is crucial to unite all teams under a single strategy to maximize its benefits.

Disadvantages of automation and process control

While automation and process control have significant advantages, they also come with drawbacks. These negative aspects are essential for a thorough evaluation:

- Replacement of human workers: Automation may eliminate jobs, raising concerns among many.

- Lack of flexibility: Automated systems sometimes struggle with unexpected situations or sudden process changes.

- Risk of errors: Errors in automated systems can be highly detrimental to a company.

- Distrust in technology: Some individuals lack complete confidence in the accuracy and reliability of automated systems and artificial intelligence (AI).

- Need for skilled labor: Automation requires technically skilled personnel, which can be costly.

It is crucial to consider these disadvantages when implementing automation and process control. Balancing benefits and risks is important for maximizing the potential of this technology.

Implementing automation and process control

To succeed in process automation, follow these steps:

- Identify repetitive tasks that could benefit from automation. According to experts, nearly 20% of time is spent on tasks that could be automated.

- Choose the right technology based on your company’s needs. Small to medium-sized enterprises could spend over $1.6 billion on automation by 2026.

- Train employees to use new systems to your advantage. A Unit4 study shows that workers spend 69 days per year on administrative tasks, costing companies $5 trillion.

- Establish controls and monitoring to adjust automation as needed. For many customers, good service means valuing their time, making automating these processes essential.

- Continuously measure and improve results. Automation boosts productivity, efficiency, and cost savings.

Adopting integrated technologies standardizes tasks, prevents improvisation, and complies with laws and regulations. Automation does not endanger human jobs; its goal is to enhance business operations and simplify process management. Facilitate management through data extraction and analysis, aiding management decision-making. It provides real-time visibility and improves access to key information, enhancing product or service quality and increasing sales and customer retention.

Automation and process control across industries

Automation and process control can be applied across a wide range of industries to enhance efficiency and reduce costs:

- Manufacturing: Automating production tasks and quality control.

- Finance: Automating accounting processes, billing, and risk management.

- Healthcare: Automating administrative tasks, data analysis, and appointment scheduling.

- Logistics: Automating storage, distribution, and shipment tracking processes.

- Technology: Automating customer support tasks, software development, and cybersecurity.

Technology automation sales in the industry have grown by 15% this year. This demonstrates how more companies are adopting these technologies. Furthermore, the use of Industry 4.0 technologies has grown 20% more than last year. Industrial automation enhances the accuracy and repeatability of tasks, improving product quality. Additionally, it aids in better process control, allowing companies to detect and resolve issues more easily.

Future trends in automation and process control

Technology is advancing rapidly, introducing new trends in automation and process control. AI systems are expected to become more sophisticated, capable of making complex decisions to enhance industrial processes. Moreover, increased connectivity through the Internet of Things (IoT) is expected, facilitating more efficient collaboration between devices and systems. Robotics and augmented reality will increasingly be used in factory environments, contributing to process precision and safety. Real-time analysis capability will be crucial, allowing systems to process information quickly and make agile, adaptive decisions. The security and privacy of automated systems will play a crucial role, with protecting data against cyber threats being essential. In summary, automation and process control will advance towards greater intelligence, connectivity, security, and sustainability.