Material flow optimization is a key concept in the field of supply chain management and industrial operations. In this article, we will explore its definition, the associated challenges, the technological solutions offered by Eurystic Solutions and the benefits it brings. This comprehensive approach will allow us to understand why material flow optimization is essential for the success of modern organizations.

What is material flow optimization?

Material flow optimization is the process of analyzing, planning, and improving the way materials move through an organization, whether within a production plant, warehouse, or entire supply chain. This process seeks to ensure that materials are in the right place, in the right quantity, and at the right time, minimizing waste and reducing operational costs.

To achieve this, advanced tools and methodologies such as simulation, artificial intelligence, and optimization algorithms are used. These technologies allow complex systems to be modeled, inefficiencies to be identified, and optimal strategies to be proposed to improve flows.

Material flow optimization not only improves operational efficiency, but also contributes to a better customer experience by ensuring faster and more reliable deliveries.

What are the challenges in managing material flows?

Despite their importance, managing material flows presents a number of challenges that can hinder the operational performance of companies. These problems often arise due to limitations in infrastructure, technology or processes. Below, we explore the main challenges:

Process Bottlenecks

Bottlenecks occur when a specific stage of the process cannot handle the amount of work required, creating delays that affect overall throughput. These problems are often caused by:

Insufficiently capable equipment.

Slow or manual processes.

Poor synchronization between flow stages.

Identifying and resolving bottlenecks is essential to ensure that materials flow continuously and efficiently through the system.

Lack of visibility and control

Without adequate monitoring tools, companies struggle to identify inefficiencies, anticipate disruptions, or adjust their processes in real time. Lack of visibility also limits the ability to respond quickly to changes in demand or unexpected problems, such as machinery failures or transportation delays.

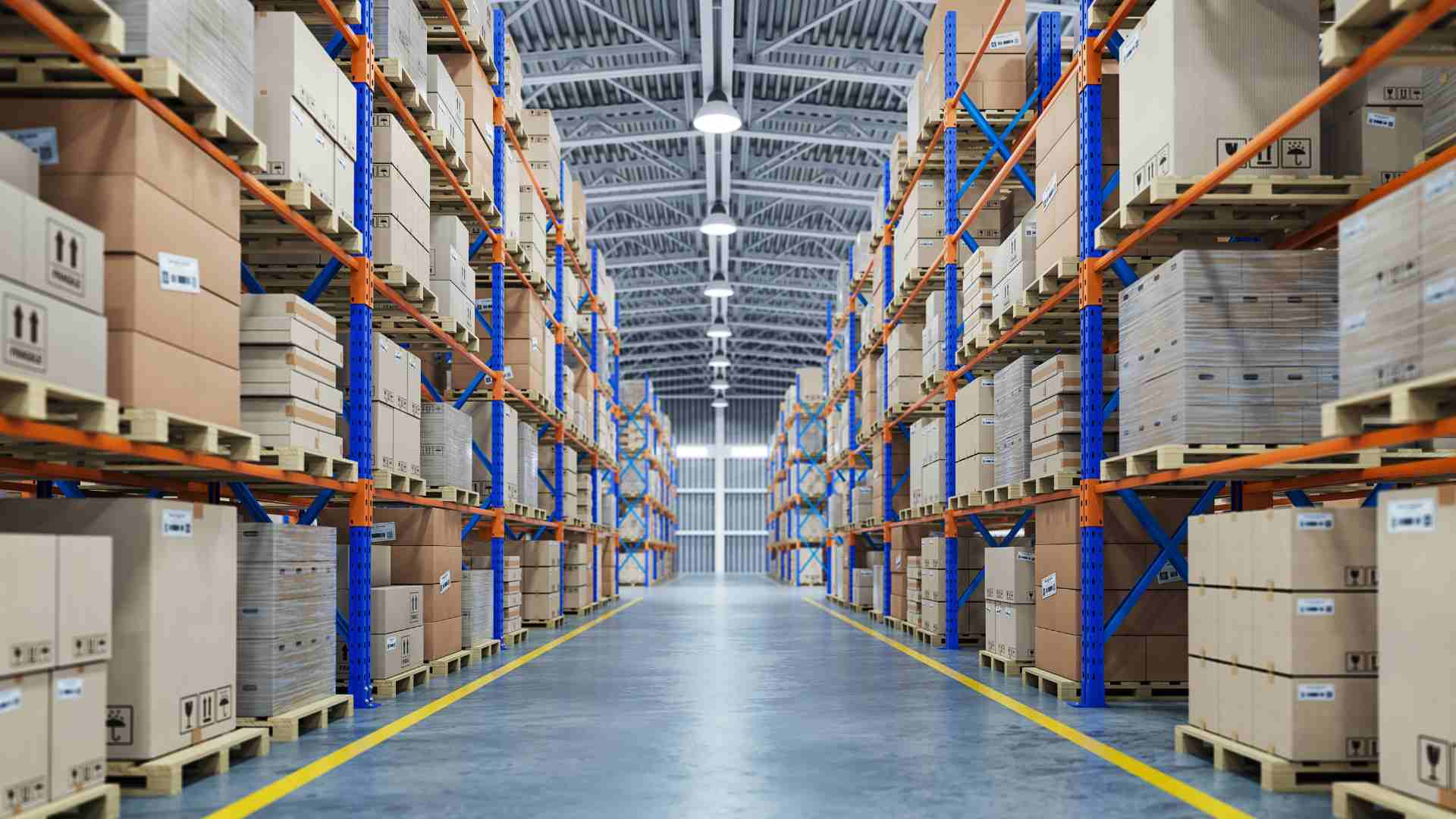

Inefficient use of resources

Suboptimal use of resources, such as storage space, personnel, or equipment, generates additional costs and reduces productivity. For example:

Excessive inventories take up valuable space and increase maintenance costs.

Unnecessary material movements increase operating time and costs.

Underutilized equipment represents a loss of investment.

Overcoming these challenges requires a structured approach that combines technology, data, and continuous improvement methodologies.

Optimizing material flows with Eurystic Solutions

Eurystic Solutions offers advanced tools and methodologies designed to address the most complex challenges in material flow management. With a data-driven approach and cutting-edge technology, its solutions help companies achieve optimal levels of efficiency and competitiveness.

Flow simulation and analysis software

Simulation allows organizations to model their processes and systems to understand how they perform under different conditions. Eurystic uses tools like AnyLogic to create accurate models that help:

- Identify bottlenecks.

- Evaluate “what-if” scenarios to make informed decisions.

- Reduce risks associated with operational changes.

Production planning and control systems

These systems integrate real-time data to coordinate production activities, manage inventories and ensure that resources are used efficiently. Eurystic solutions enable:

- Synchronize production with market demand.

- Improve resource allocation.

- Reduce downtime.

Automation solutions

Automation is one of the most effective strategies for improving material flows. The most innovative solutions include:

Automated transport systems (AGVs)

Automatic Guided Vehicles (AGVs) optimize the internal transport of materials, ensuring faster, more precise and safer movements.

Collaborative robots (cobots)

Cobots work alongside human operators on repetitive or dangerous tasks, improving safety and increasing productivity.

Automated Storage and Retrieval Systems (AS/RS)

Benefits of material flow optimization

Implementing optimization strategies in material flows offers significant benefits, both at operational and strategic levels. These include:

Reduction of operating costs

By eliminating inefficiencies, companies can significantly reduce their costs associated with transportation, storage, and labor. For example, automating manual processes decreases the need for human intervention, reducing errors and labor costs.

Improving efficiency and productivity

Optimization ensures that resources are used optimally, increasing the speed and quality of processes. This allows companies to produce more with fewer resources and in less time.

Greater customer satisfaction

With optimized processes, companies can meet delivery deadlines, ensure product quality, and adapt quickly to changes in demand. This improves customer experience and strengthens brand loyalty.

Reducing environmental impact

More efficient processes generate less waste and consume fewer resources, contributing to business sustainability. For example, optimizing logistics routes reduces carbon emissions and fuel consumption.

Conclusion

Material flow optimization is an indispensable strategy for companies looking to stay competitive in an increasingly demanding market. With the support of Eurystic Solutions, organizations can overcome operational challenges, implement innovative solutions, and reap significant long-term benefits. Whether through simulation, automation, or optimization, Eurystic is poised to take companies to the next level of efficiency and sustainability.