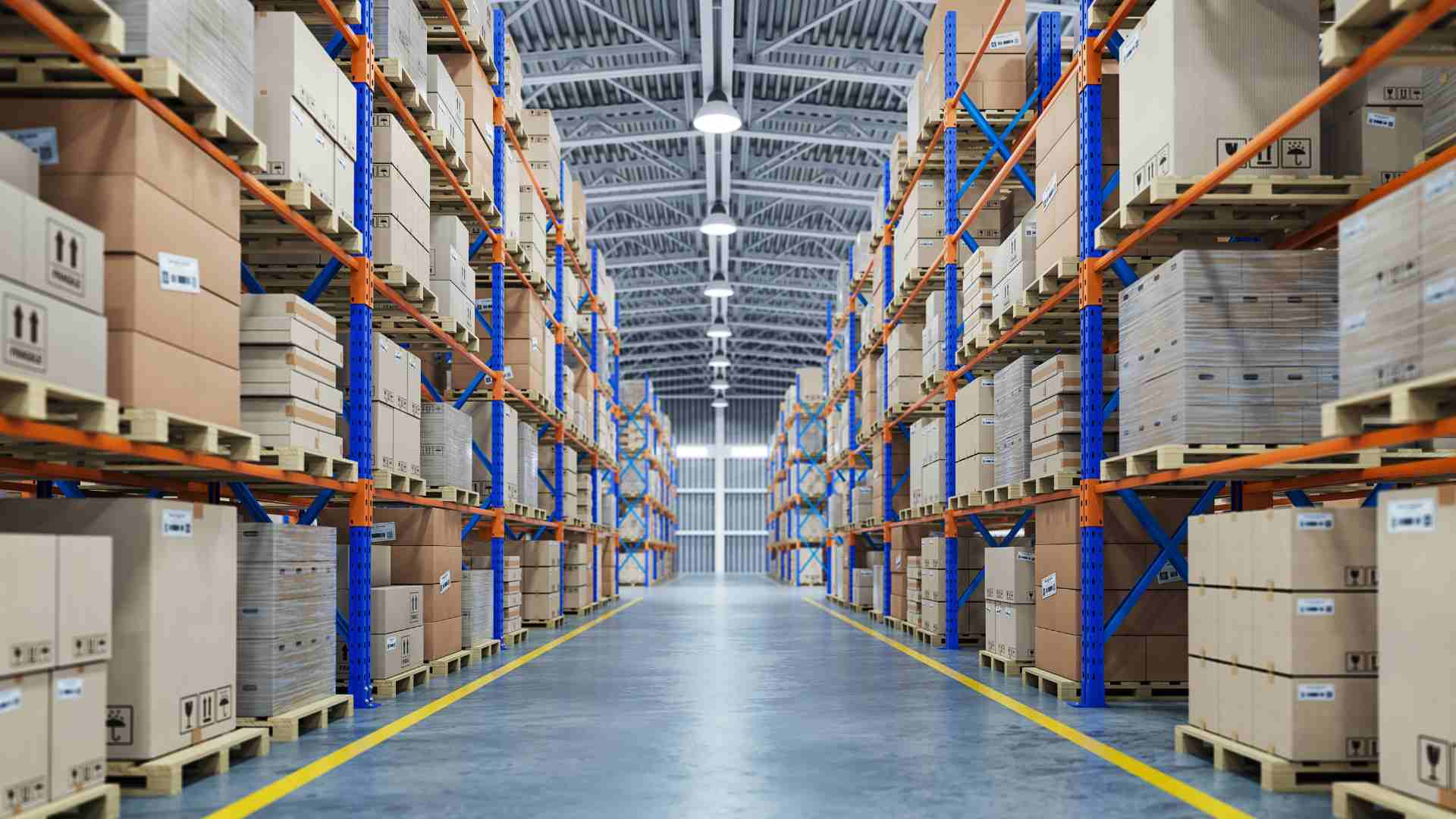

Efficient warehouse management is essential for any company handling inventory. In this article, we will explore in detail the Storage Location Assignment (SLAP) and how it can optimize your business’s logistics operations.

What is Storage Location Assignment (SLAP)?

Storage Location Assignment, known as SLAP (Storage Location Assignment Problem) in English, is a strategic system that determines the optimal placement of products within a warehouse. This method takes into account factors such as picking frequency, product characteristics, available space, and demand patterns to maximize operational efficiency.

Differences Between SLAP and Other Storage Systems

Unlike traditional systems that assign locations randomly or based solely on categories, SLAP uses a scientific approach and analytical data to optimize product positioning. While conventional systems can lead to inefficiencies and prolonged picking times, SLAP significantly reduces these problems by considering multiple real-time variables.

Benefits of Implementing SLAP in Warehouses

Implementing SLAP offers numerous advantages for warehouse operations. Some of the most notable benefits include reducing picking times, optimizing storage space, decreasing order fulfillment errors, and improving inventory turnover. Additionally, it helps reduce operational costs and increase staff productivity.

Location Assignment Methods

Fixed Assignment

This method establishes permanent locations for each SKU, ideal for products with stable demand and constant storage volume. Fixed assignment makes it easier for staff to memorize locations and simplifies picking processes. It is ideal for high-demand products or those requiring special storage conditions (refrigeration, security, etc.). However, it may not be as efficient if demand fluctuates frequently, as spaces may remain idle if a product runs out or has lower temporary turnover.

Dynamic Assignment

Dynamic assignment allows flexibility in product placement based on current warehouse conditions. This method adapts to changes in demand and continuously optimizes the use of available space, though it requires more sophisticated management systems. It can generate space savings and reduce travel times but requires meticulous management and technological support to avoid confusion.

Mixed or Hybrid Assignment

This method combines elements of both fixed and dynamic assignment, offering a balance between stability and flexibility. Some high-rotation or specifically-needed products maintain a fixed location, while others, typically with medium or low turnover, share storage areas according to demand. This is especially useful for warehouses with different types of products and variable demand patterns.

Tools for Optimizing SLAP

Warehouse Management Software (WMS)

Modern WMS systems include specific features for SLAP, enabling automated location management, real-time inventory tracking, and continuous optimization of space assignments.

Automation with Technological Solutions

The integration of technologies such as RFID, QR codes, and light-guided picking systems significantly improves the accuracy and efficiency of SLAP implementation. The implementation of picking robots, smart conveyors, and identification technology (such as RFID) streamlines the location assignment and retrieval processes. Additionally, it reduces dependence on human labor for repetitive tasks and decreases the likelihood of errors.

How to Implement SLAP in Companies?

Successful implementation of SLAP requires a systematic approach that includes historical data analysis, evaluation of demand patterns, staff training, and the selection of appropriate technological tools. It is essential to establish clear metrics and make continuous adjustments based on performance.

Key Steps:

- Initial inventory and operation analysis: Collect data on product rotation, volumes, picking frequencies, and demand projections.

- Layout design and assignment method definition: Select the storage structure and assignment type (fixed, dynamic, or mixed).

- WMS Implementation: To handle and monitor location assignments in real-time.

- Staff Training: Ensure the entire team understands the guidelines for the new assignment system, WMS usage, and optimal picking routes.

- Monitoring and Continuous Adjustments: Periodically review performance indicators to adjust locations based on demand changes.

Can Efficiency Be Improved with SLAP?

The implementation of SLAP can significantly improve operational efficiency. Proper storage location assignment reduces unnecessary travel, decreases search times for products, and optimizes the use of available space. This translates into higher productivity, lower logistics costs, and better customer service due to faster and more accurate order fulfillment.

Companies that adopt this system report improvements of up to 30% in picking times, a 25% reduction in operational costs, and a 40% increase in inventory accuracy.

Examples of Successful SLAP Implementation

Numerous companies have achieved outstanding results with SLAP. For example, a major pharmaceutical supply chain reduced its order fulfillment times by 45% after implementing an SLAP system with a hybrid assignment method. Another notable case is an electronics distributor that increased its storage capacity by 35% without expanding its facilities.

Storage Location Assignment represents a comprehensive solution to modern warehouse management challenges. Its implementation, though requiring an initial investment in technology and training, offers significant long-term benefits in terms of operational efficiency and cost reduction.