Simulation Software: What Is It? A Tool for Engineers and Designers

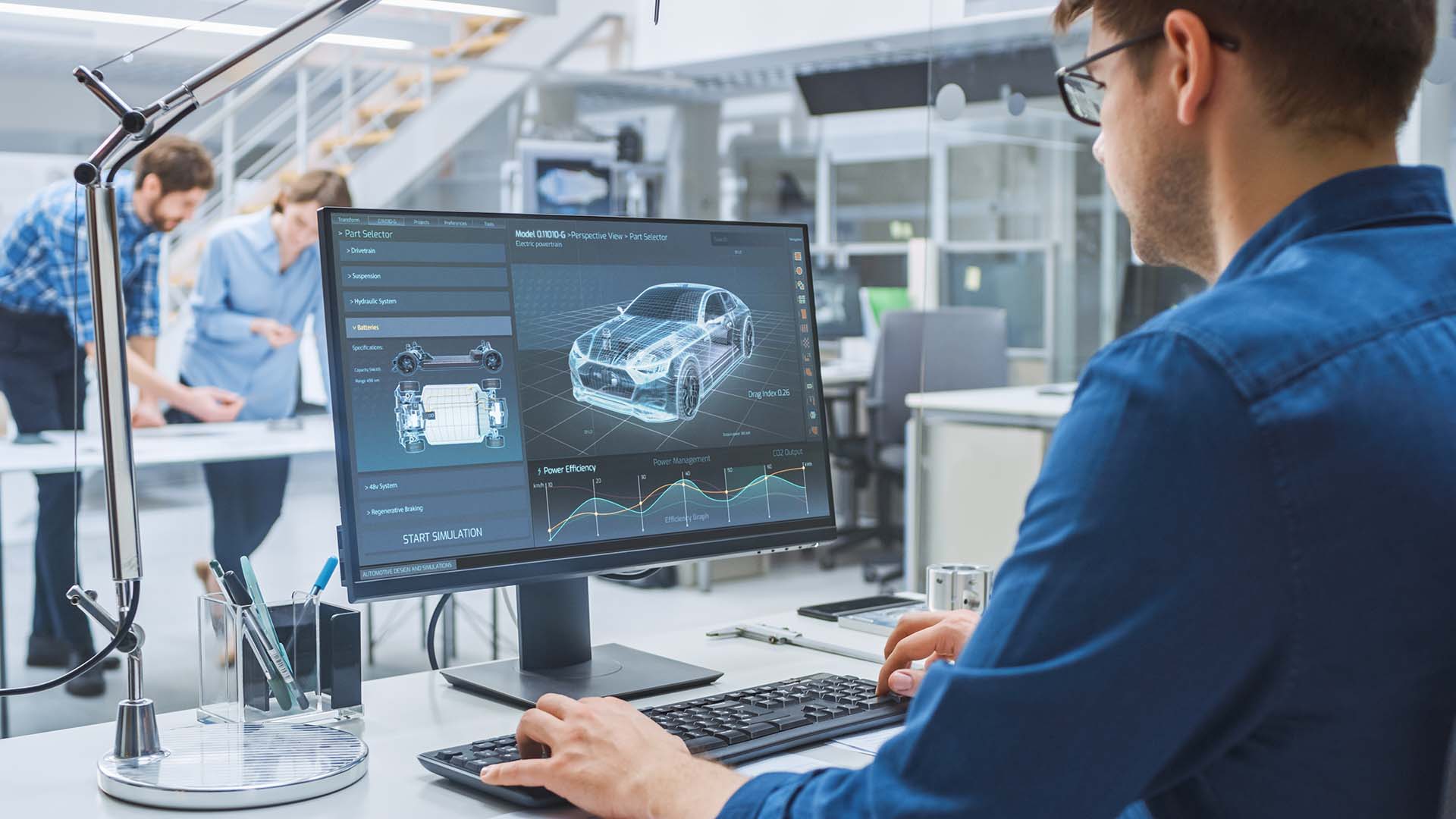

Simulation software, essential for engineering and design professionals, has revolutionized how they tackle their challenges. With advanced tools like AnyLogic, Arena, and Simio, designers can work with an exceptional level of detail, modeling and simulating systems with extraordinary precision.

The combination of simulations and detailed analyses enables the creation of highly accurate models that cover everything from industrial processes to complex logistical operations. Advanced simulation allows real-time design improvements, increasing both the performance and efficiency of the developed products and processes.

Simulation in Logistics and Process Design

As the complexity of various areas of operations and logistics grows, simulation becomes an indispensable tool for refining these processes and ensuring operational efficiency. Various programs are used to simulate everything from complex supply chains to advanced production systems.

The reports generated from simulations play a crucial role in project design and analysis, providing industry experts with a deep understanding of the obtained data, thus optimizing their operations and designs.

Innovative organizations like Eurystic have introduced platforms that streamline modeling. Tools like AnyLogic, Arena, and Simio not only contribute to cost reduction but also significantly shorten modeling times.

Continuous advances in software, supported by increasing computational power, are fundamental for conducting extremely precise virtual tests. This allows engineers to significantly refine their designs before bringing them to production.

Simulation Software in Industrial Innovation

Simulation software has changed the way industrial processes are designed and created. Engineers can test different designs and processes in a virtual world, saving time and money. Additionally, it improves the performance of equipment and processes.

Using computational simulations accelerates the development of industrial projects by allowing engineers to refine a design before construction begins, shortening execution times, and preventing costly errors.

Performance Optimization in Industrial Processes

For existing processes, such as production lines and logistics systems, simulation is key because it helps them operate better and meet expected performance standards. This is vital to keep industrial systems working efficiently.

Is Simulation Software a Strategic Investment in Engineering?

Investing in simulation software is very wise for engineering companies. It helps reduce costs by using virtual models to test designs and processes before starting actual physical production.

By simulating how equipment and processes work, companies avoid errors and improve designs, becoming more efficient and more profitable.

Additionally, by using simulation software, companies achieve significant savings by avoiding the need to create physical prototypes. This approach not only speeds up the development process but also ensures that products reach the market more quickly and in optimal conditions. Thus, companies achieve success more efficiently.

Simulation and Equipment Lifespan Prediction

Simulation is not limited to the design of new products; it also plays a crucial role in predicting the durability of existing equipment. This allows companies to avoid costly downtime by planning maintenance and equipment replacement in advance.

This precise planning helps control operating expenses and maintain continuity in industrial processes.

Increasing Competitiveness in Various Industrial Sectors

In addition to reducing costs, simulation significantly improves the quality and efficiency of industrial processes. This approach allows companies to stand out in the market and outperform the competition.

By implementing simulations, companies achieve more efficient, faster, and optimized production in resource usage. This capability is essential for maintaining a competitive edge in any industrial sector.

Simulation for Control System Design

Simulation has radically transformed how we design control systems. Today, software provides us with advanced tools to model and optimize these systems from the beginning of the process.

This allows us to identify and correct potential operational issues before they become real obstacles, which is fundamental to ensuring the effectiveness of the systems.

In the field of autonomous systems engineering, simulation plays a crucial role in designing control logics and visualizing behavior. For example, designing crane automation in a warehouse presents a challenge to ensure the systems behave as expected under a vast universe of scenarios.

In such cases, simulation allows for exhaustive testing to avoid inefficient implementation of the real system.

Simulation also offers effective methods for evaluating and comparing different approaches in control systems. It allows engineers to analyze key measures such as efficiency and reliability, facilitating the selection of the most suitable method for the specific needs of the system.

This detailed analysis capability helps continuously optimize systems and ensure their optimal performance under various operating conditions.

Simulation Tools in Design

Simulation tools are key in the design of processes and infrastructures. They help designers create detailed models and simulate how these systems will operate. This makes design easier, more efficient, and cheaper.

These tools integrate well with CAD software, meaning design models can be used in simulations. Simulations can reference the actual layout of a warehouse or industrial center to study the advantages or disadvantages of a particular design.

This simulation approach greatly helps in evaluating a finite number of potential designs and quantifying their performance.

Model Verification for Safe Implementation

Verifying models is critical in simulation design. Their accuracy and reliability must be confirmed by comparing the models with real data and testing them based on actual, projected results or industry expert experience. This ensures the design is done correctly in reality.

Applications and Examples of Simulation Software

The applications of simulation software are vast and varied:

- Improving design accuracy: Makes equipment more efficient and better predicts downtime and failures, facilitating predictive maintenance.

- Identifying and solving production problems: Improves factory efficiency and safety, and helps save on maintenance by pinpointing heavily loaded equipment.

- Designing industrial and logistical processes: Helps visualize and improve design and operation by collecting essential KPIs for decision-making.

In various industries, simulation plays a crucial role in fostering innovation and improving operational efficiency. For example, in manufacturing companies, it is used to optimize manufacturing processes by detecting dynamic bottlenecks that may occur under certain scenarios.

It is common for complex production processes with a variable production mix to require a simulation study to explore potential improvements and investments.